Our unwavering commitment revolves around one fundamental principle: exceptional customer service. We understand that empty promises followed by disappointment are not the path to success. Since our inception, we have made it our paramount mission to deliver nothing short of top-tier service, ensuring the absolute satisfaction of each and every customer. Our journey to excellence has been paved with continuous dialogue with our valued customers and trusted suppliers, propelling us toward remarkable achievements.

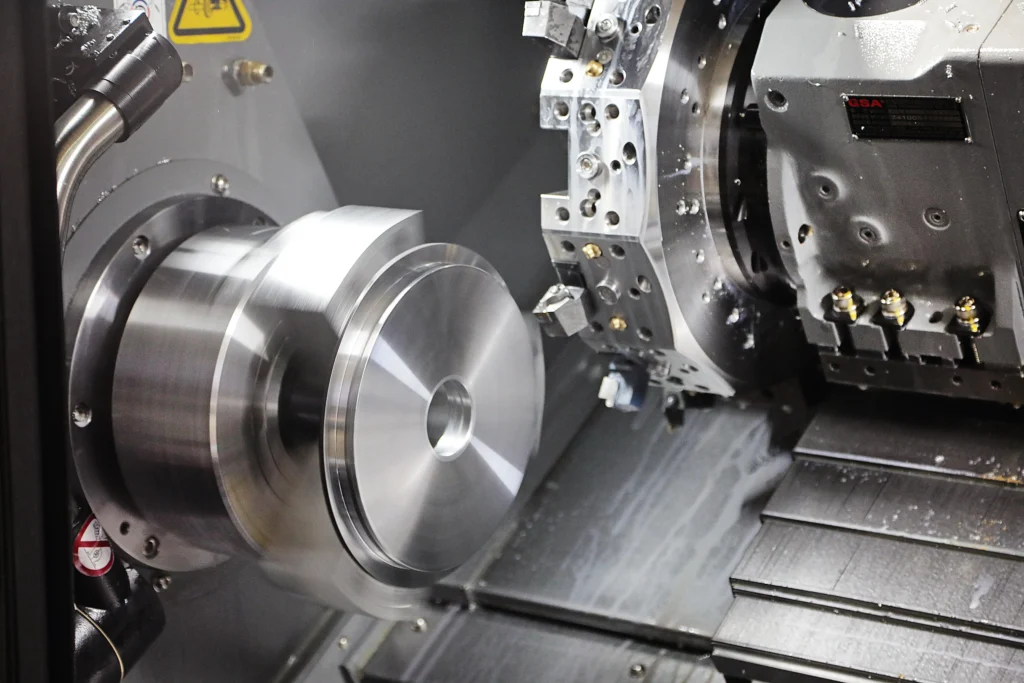

Integrity Tool has established a strong customer base firmly rooted in trust and integrity. We specialize in supplying precision parts for various industries, including optics, automotive, food, and aerospace, among others.

In 1996, we asked God to bless an idea, and Integrity Tool was born. Work began in a small barn with one mill and one lathe. With some well-placed cold calls, we quickly established a small customer base. Equipment was added and employees were hired. As the business expanded, we continually upgraded our equipment and hired more employees. With space in the barn being only 1500sq ft. we quickly ran out of room for our expanding business.

In April of 2000 we moved to a larger facility, increasing our floor space. With relentless dedication and unwavering communication with our clients and vendors, Integrity Tool continued to thrive, even in challenging times. And in just seven years, our growth necessitated yet another facility upgrade.

In 2007, Integrity Tool acquired prime land within the Ontario Industrial Park, embarking on the construction of our modern 6000sq ft. facility. Today, this houses all aspects of our operations, including machining, fabrication, and administration. In 2023, we took yet another step forward, expanding our workspace by an additional 4000 square feet to accommodate new larger equipment, establish a dedicated stock room, and create a dynamic fabrication and weld shop. These strategic expansions bolster our capacity to meet an even broader spectrum of our customers’ needs

Wondering if we can manufacturer the part you require? Curious if our milling capabilities can meet your needs? Browse our FAQs for answers to your questions. If we don’t address your question below, contact our team today!

Integrity Tool stands out through our commitment to precision, customer service, and efficiency. We combine decades of experience with advanced technology to deliver exceptional results, ensuring every component we produce meets the highest standards.

Integrity Tool has been producing quality components to some of the same customers for over 25 years. Our commitment to maintaining customer relationships is at the core of our business model.

The demand for quality and on time deliveries is challenging. We do our best to maintain delivery requirements through constant communication with our customers.

Our experienced management team has over a century of combined machining and production experience. We work as a tight-knit unit to ensure that our customers needs are met in a timely manner. We employ a team of highly skilled tool makers, dedicated in producing top quality products using lean manufacturing.

Quality Manager